You are here:

>

Products

>

Anodising Aluminum Sheet/ Coil

>

Anodized aluminium coil for aluminium honeycomb board

Anodized aluminium coil for aluminium honeycomb board

Description

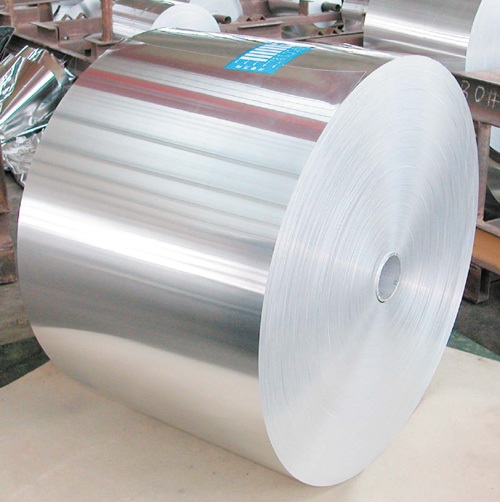

- Alloy:1100,1050,3003,5005,5052,5083,8011

- Temper:H14,H24,H18,H19,H22,H26,H32,H112

- Thickness:0.27-4.0mm

- Width:300mm-1900mm

- ID:76mm,152mm,405mm,505mm

- Oxide film:15mu

- Temperature resistance: Min:250 °C

- 5% salt fog: Min1000 h

- Color:Gold,silver,bronze etc

- Package: Standard seaworthy package ,wooden boxes package or wooden pallet.

- Delivery time:With 25 days after deposit

Regular size

- 0.5*1000*Coil 1.5*1000*Coil 1.0*1250*Coil

- 2.0*1250*Coil 2.0*1250*Coil 1.25*1000*Coil

- 1.25*1000*Coil 3.0*1000*Coil 3.0*1250*Coil

- 3.0*1500*Coil 4.0*1000*Coil 4.0*1250*Coil

- 4.0*1500*Coil 1.0*1000*Coil 1.0*1500*Coil

Application

- Anodized aluminium coil can apply to Lighting,solar reflective film,building appearance, Radiator ,Condenser, Insulation Material.

- Anodized aluminium coil as interior decorating:Ceilings,walls, furniture,cabinets,elevators, signs, nameplates,bags,automotive.

- Anodized aluminium coil is used in Photo Frame;household appliances:refrigerators,microwave ovens,audio equipment,etc.

- Anodized aluminium coil is used in aerospace and military aspects, such as China's large aircraft manufacturing,the Shenzhou spacecraft series,satellite.

- Anodized aluminium coil is used in the mechanical parts processing,mold making,chemical/thermal insulation pipes coated.

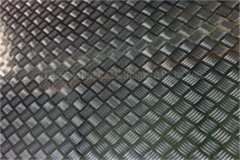

- Anodized aluminium coil is widely used for metal aluminium ceiling,curtain wall plate,aluminium plastic panel,fire-proof plate,aluminium honeycomb board,aluminium single board,electrical panel

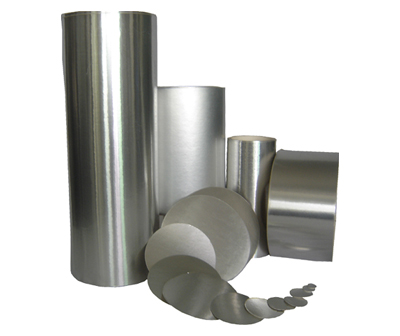

- Anodized aluminium coil for aluminium honeycomb board Photos

Feature

1. Good workability, high oxidation aluminium plate, adornment sex is strong, moderate hardness, can be easily bending forming, continuity high-speed stamping, convenient and directly processed

into products, surface treatment need not be complicated, greatly shorten the product production cycle and reduce the production cost.

2. Good weather resistance: anodized aluminum with oxide film standard thickness is 3 microns, that is uded in indoor can hold long-term nondiscoloration, no corrosion, no oxidation, no rust.

With thick oxide film (10 microns) the anodized aluminium plate can be used in outdoor, can be long-term exposure to light discoloration.

3. Strong metal feeling: the anodization of aluminum plate surface hardness, grade gems, good scratch resistance, surface paint coverage, keep aluminum sheet metal color, highlight modern

metal feeling, improve the product grade and added value.

4. High flame-retardant: pure metal products, surface without any chemical material, paint and 600 degrees high temperature does not burn, do not produce poisonous gas, conform to the

requirements of the fire control and environmental protection.

5. The fouling resistance is strong, not hand, there will be no stain marks, easy to clean, do not produce corrosion spots.