Clod Stamped Aluminum,cold forming blister aluminum,CFA,CFB

Certificate: TDS, COA, ISO9001,

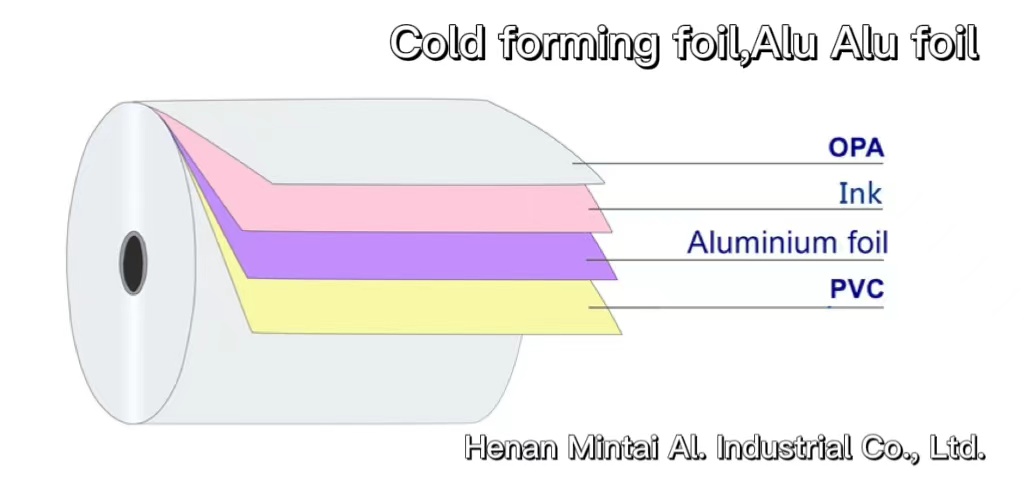

Cold Formed OPA/Al/PVC Sandwiched Foil For Blister Packs

About Cold Formed Alu Alu Foil :

Cold formed aluminum foil is at the heart of alu alu OPA/Al/PVC sandwich foils used for pharmaceutical blister pack applications because of their inherently superior advantages. Aluminum, even in micron thickness, is the best vapor and light barrier besides providing aesthetic shine for pharmaceutical blister packs.

What is pharmaceutical Cold forming foil?

Pharmaceutical Cold forming foil is made of aluminum foil, nylon (oPA) and PVC films, by using dry bond lamination technology. As blisters are formed at room temperature, without heating, so it is called as cold forming blister laminated foil.

Cold forming foil is one type of triplex packaging material, between each two layers, there is adhesive for lamination. The adhesive we are using is imported from USA, to ensure good performance during cold forming process, such as no delamination and cracking.

Structure: