You are here:

>

News

>

Aluminum Alloy Quenching-6061/6063/7075/7075 temper-T6/T651/T4

Aluminum Alloy Quenching-6061/6063/7075/7075 temper-T6/T651/T4

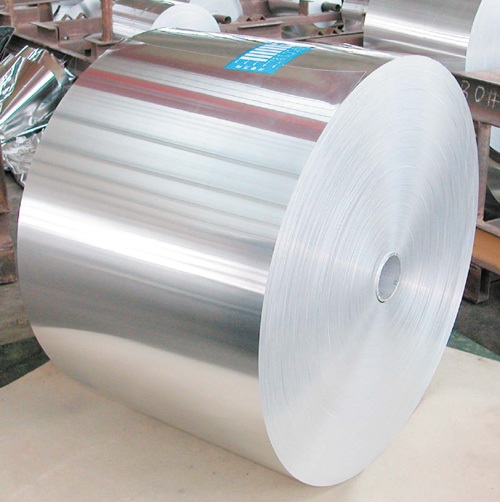

Aluminum Alloy Quenching to produce the aluminium sheet,aluminum plate.The production including alloy 6061,7075,6063,7050,2024,7178,

Temper:T6,T651,,T4,T5,T61.Thickness:0.5-50mm.

Aluminum are widely used in industrial, construction, decoration, capacitor, packing material. And the application for

PS/CTP/ACP plate base, aluminum and plastic composite board/pipe/bottle/tank cap, aluminum for curtain board

board/roofing, the aluminum for refrigerator/air conditioning/automobile and so on.

The cooling rate of the aluminum alloy quenching furnace must ensure that the saturated solid solution is fixed.

Prevention of strengthening phase precipitation, reducing the mechanical properties of the quenching time. So the

cooling rate of quenching is faster. However, the greater the cooling rate, the greater the residual stress and residual

deformation of the quenched products, so the cooling rate should be determined according to different alloys and

different shapes and sizes.

The quenching speed of the alloy is sensitive to the cooling rate, and the cooling rate is high. Such as 2A11, 2A12

alloy quenching cooling rate should be at 50 /S above, and 7A04 alloy is very sensitive to the cooling rate, the

quenching cooling rate is above 170 /S.

For different products with different cooling rate, the temperature of the quenching medium should be adjusted.

The experimental results show that the mechanical properties and corrosion resistance of the quenched products

are decreased with the increase of water temperature.

The most commonly used quenching medium for aluminum alloy quenching furnace is water. Because of the low

viscosity of water, large heat capacity, rapid evaporation, cooling capacity, and the use of very convenient, economic.

But its disadvantage is that the cooling capacity is reduced after heating.

In order to ensure that the quenching product cooling evenly, need to be in the quenching tank with compressed air

pipe, so as to stir, and at the same time to make the product into the sink to make appropriate swing. In addition to

ensure that the water temperature will not rise too much, the quenching tank should have enough capacity (generally

should be more than 20 times the total volume of the quenching products). And cooling water should be circulating

device.

In addition to regulating the water temperature to control the quenching cooling rate of the aluminum alloy quenching

furnace, the cooling capacity of the water can be adjusted by adding different solvents in the cooling water. It is usually

used as the cooling medium, and it can adjust the concentration of ethanol water solution to control the cooling rate

of quenching. Commonly used products, often used in the solution of ethanol water to quench.

We can supply aluminum plastic composite panel,Color Coated aluminum coils ,PVDF Coated aluminum coils, Aluminum tread plate,aluminum circle,aluminum foil,aluminum sheet,aluminum plate,Household Foil, Air-container Foil, Cable Foil, Electronic Capacitor Foil, Medicine Foil,Blister Foil, Flexible Packaging Foil, Aluminum Sheet, Aluminum Coil,CTP Stock, Litho Stock, Cap Stock,Aluminum Tread Plate, Embossed Coil, Mirror Panels, Cans Cover Materials, Aerospace Aluminum, Mold Aluminum Materials, etc. At the same time, we also accept OEM/ODM production according to requirements of customers.

Whenever you have a need for any of our products, please feel free to contact us .

Henan Mintai Al.Industrial Co., Ltd is located in China's central commercial hub—Zhengzhou. It is one of best and bigest private Aluminum Industrial Co.Ltd in China.

Office Add:No.1043 room in Weilai International,No.25# building CBD business inner ring Zhengdong New district,Zhengzhou,Henan,P.R.China

Tel:+86-371-680845488

Fax:+86-371-68068199

E-mail:mary@mintaialuminum.com

Web:http://www.mintai-aluminum-coils.com