You are here:

>

News

>

Casting and Classification of Aluminum Rods

Casting and Classification of Aluminum Rods

1). and the casting of an aluminum rod

Casting includes melting, purification, purification, gas, slag and casting process. The main process is:

(1) Ingredients: according to the needs of the production of specific alloy grades, calculate the amount of various alloy composition, reasonable collocation various raw materials.

(2) Melting: the raw materials will be prepared by the process to be melted in the furnace, and the slag and gas can be effectively removed by the addition of gas and slag refining method.

(3) Casting: the molten aluminum liquid in a certain casting process conditions, through the deep well casting system, cooling casting into a variety of specifications of the round cast rod.

2). the classification of aluminum rods

1. according to the different content of alloy elements aluminum sheet can be divided into: 1 * * * Department of industrial pure aluminum), 2 * * * series for Al Cu alloy aluminum (Al--Cu), 3 * * * for manganese aluminum alloy aluminum (Al--Mn), 4 * * * aluminum silicon alloy aluminum (Al--Si) and 5 * * * for aluminum magnesium alloy aluminum (Al--Mg), 6 * * * series AL--Mg--Si aluminum magnesium silicon alloy plate, 7 * * * (Cu) aluminum zinc alloy aluminum [AL--Zn--Mg--, 8 * * * system for aluminum and other elements. Each series also with three, each position to numbers or letters, the meaning is: the second digit said the number of controlled impurities; the third and fourth digits represent pure aluminum content percentage of decimal point after the minimum content.

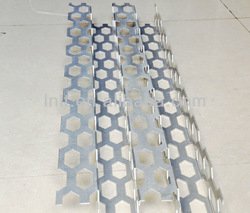

2. According to the shape can be divided into: round aluminum rod, aluminum rod, six angle aluminum rod, ladder shaped aluminum rod, etc.

Casting includes melting, purification, purification, gas, slag and casting process. The main process is:

(1) Ingredients: according to the needs of the production of specific alloy grades, calculate the amount of various alloy composition, reasonable collocation various raw materials.

(2) Melting: the raw materials will be prepared by the process to be melted in the furnace, and the slag and gas can be effectively removed by the addition of gas and slag refining method.

(3) Casting: the molten aluminum liquid in a certain casting process conditions, through the deep well casting system, cooling casting into a variety of specifications of the round cast rod.

2). the classification of aluminum rods

1. according to the different content of alloy elements aluminum sheet can be divided into: 1 * * * Department of industrial pure aluminum), 2 * * * series for Al Cu alloy aluminum (Al--Cu), 3 * * * for manganese aluminum alloy aluminum (Al--Mn), 4 * * * aluminum silicon alloy aluminum (Al--Si) and 5 * * * for aluminum magnesium alloy aluminum (Al--Mg), 6 * * * series AL--Mg--Si aluminum magnesium silicon alloy plate, 7 * * * (Cu) aluminum zinc alloy aluminum [AL--Zn--Mg--, 8 * * * system for aluminum and other elements. Each series also with three, each position to numbers or letters, the meaning is: the second digit said the number of controlled impurities; the third and fourth digits represent pure aluminum content percentage of decimal point after the minimum content.

2. According to the shape can be divided into: round aluminum rod, aluminum rod, six angle aluminum rod, ladder shaped aluminum rod, etc.