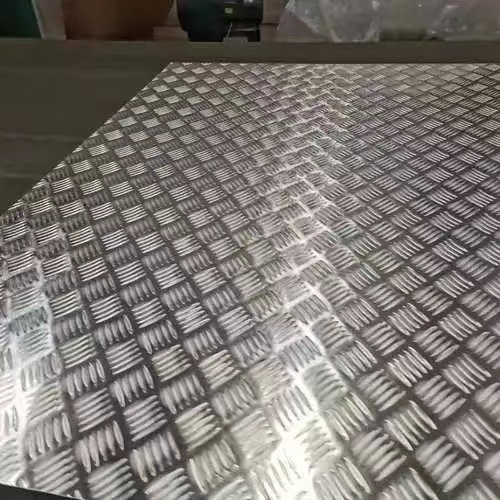

PS Base with Aluminum Fabrication Steps

Printing PS version of the base method for producing aluminum sheet, characterized in that it is the method steps:

A. according to the parts by weight ratio of Al: 98, Si: <1.0, Fe: 0.3 ~ 1.0, Cu: 0.03, Zn: 0.03, Mg: 0.03, Ti: 0.05 ratio will be above the melting temperature of the alloy composition after mixing 720 - under the conditions of 800 ℃ melting;

B. then for the next casting temperature condition of 690 ~ 750 ℃ alloy casting into ingot;

C. alloy ingot to make the ingot at a temperature of 500 ~ 610 ℃ conditions homogenization;

D. then subjected to hot rolling at a temperature of 400 ~ 540 ℃ temperature;

E. hot-rolled material consisting of 9.0mm cold-rolled to 0.7mm;

F. at a temperature of 300 ℃ ~ 500 ℃ conditions of intermediate annealing 11h, insulation 1h then cold rolling to 0.15mm, stretched, fully straightening, after cutting to be finished.