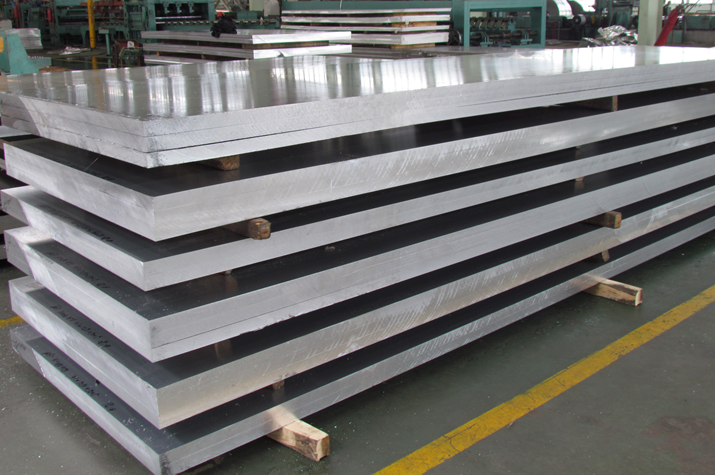

5083 Aluminum plate

5083 aluminium plate description

- Alloy:5083

- Temper:H116,H321,H111,H112,HO

- Thickness:6mm-350mm

- Width:800mm-1800mm

- Length:800mm-10000mm

- Product standard:GBT ,JIS4000, EN485, ASTM928,ASTMB209

- Protection:paper inter layer,white film,blue film,black-white film,micro bound film,

- according yo your requirement.

- Surface:clean and smooth,no bright speck,corrosion,oil,slotted,etc.

- Weigth:about 2mt per pallet

- Package:export standard package,wooden pallet with fumigation

- Delivery time:about 30days after receiving the deposit

- Payment:TT

- Trading terms:FOB,CIF,CFR

- Product standard:GBT,JIS ,EN,ASTM

- We can supply the Form E, Form A,CO and so on

5083 aluminium plate chemical composite

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | |

| GB/T3190-2008 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | REM. |

| INNER QUALITY STANDARD | 0.15-0.25 | 0.2-0.33 | 0.03-0.07 | 0.45-0.6 | 4.2-4.7 | 0.1-0.2 | 0.15 | 0.015-0.03 | REM. |

5083 aluminium plate mechanical properties

| Temper&Thickness | Tensile strength Mpa | Yield strength Mpa | Elongtion % |

| H116/T:1.0-40mm | min305 | min215 | min8 |

| H116/T:>40mm | min285 | min200 | max10 |

| H321/T:1.0-40mm | min305 | min215 | min8 |

| H321/T:>40mm | min285 | min200 |

max10 |

5083 aluminium plate properties

- in not heat treated alloy strength

- good corrosion resistance

- good machinability

- arc welding performance is good

- the anode surface is beautiful

5083 aluminum plate is widely used for ships,vehicles,aircraft components,metro lifht rail,liquid tank car,refrigerated trucks,refrigerated container,cooling device,television toaer,drilling equipment,transportation equipment,missile component and armor,etc.

Another alloy aluminium plate

Chemical Properties

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.A1 |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.6 |

| 1070 | 0.25 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.7 |

| 1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.1 | - | - | - | 0.05 | 99 | |

| 1200 | 1.00 | 0.05 | 0.05 | - | - | - | 0.1 | - | - | 0.05 | 0.05 | 99 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | - | - | - | 0.15 | Remainder |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | Remainder |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | - | 0.4 | - | - | 0.1 | 0.15 | Remainder |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.1 | - | 0.25 | - | - | 0.1 | 0.15 | Remainder |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | - | - | 0.1 | - | - | 0.15 | 0.15 | Remainder |

| 3104 | 0.6 | 0.8 | 0.05-0.25 | 0.8-1.4 | 0.8-1.3 | - | - | 0.25 | - | - | 0.1 | 0.15 | Remainder |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | - | 0.25 | - | - | - | 0.05 | Remainder |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | - | - | 0.15 | 0.05 | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | - | - | - | 0.05 | Remainder |

| 5182 | 0.2 | 0.35 | 0.15 | 0.2-0.5 | 4.0-5.0 | 0.1 | - | 0.25 | - | - | 0.1 | 0.05 | Remainder |

| 5754 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | - | - | - | 0.05 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | - | - | 0.15 | 0.05 | Remainder |

| 7075 | 0.4 | 0.5 | 1..2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | - | 5.1-6.1 | - | - | 0.2 | 0.05 | Remainder |