You are here:

>

News

>

Process for Copper and Tin Plating on Aluminum Foil

Process for Copper and Tin Plating on Aluminum Foil

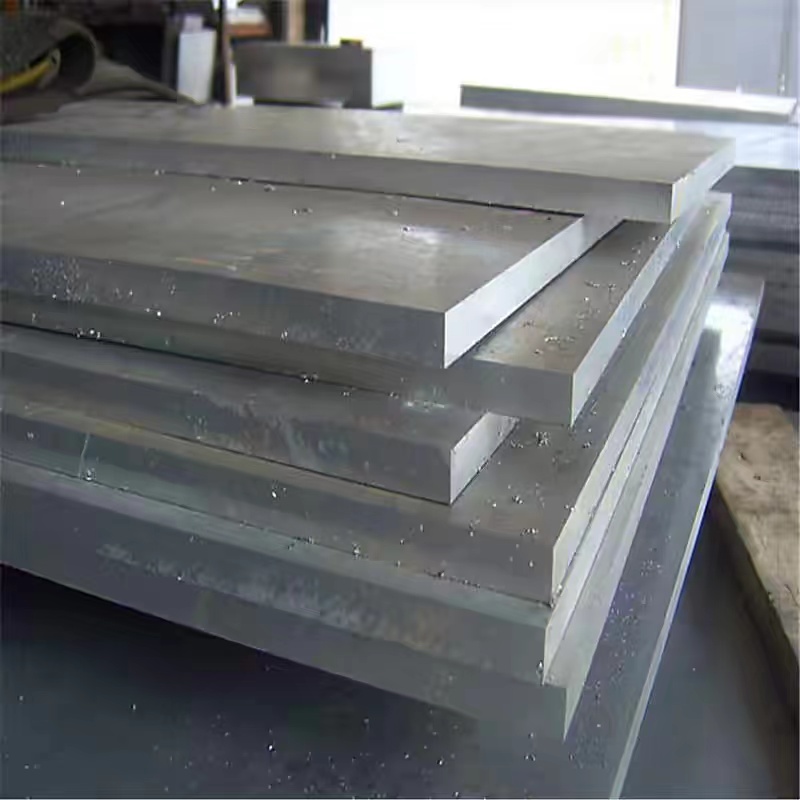

Aluminum foil is lightweight, airtight, and good cladding etc. a series of advantages, has been widely used in electronics, packaging, construction and other areas, especially the innovation of new biological engineering, power, and environmental protection related skills, the use of aluminum foil and urgent need to develop the scope of application and related technology to broaden more and more broad. Aluminum is a very vivid metal, with a high degree of affinity, in which the surface is very simple composition of the oxide film, to bring a lot of hard aluminum foil. To obtain an excellent plating layer on the aluminum foil, the disposal of the plating is a vital process.

In the field of electronic applications, to add the aluminum conductive and weldability, demand in the appearance of electroplating copper and tin metal, the current many domestic and foreign research mostly use chemical way, prepreg and electroless plating combined and disposal technology is mixed and disorderly. The author through a lot of experiments, the choice of surface plasma cleaning and magnetron sputtering intermediate layer of pre disposal methods and technology of electroplated, on the surface of the aluminum obtained crystalline detailed, bright, good weldability, combined with strong copper, tin. In aluminum foil surface electroplating certain thickness of copper to replace the use of copper foil, widely used in electromagnetic shielding category, printed circuit boards and lithium ion battery fluid, and save a lot of copper; can be singly used for electroplated coatings of tin or copper and tin coating and application in some new electronic category.

Technical introduction

Data

The hard light foil with a thickness of LG3 is used to 0.033mm the high purity aluminum rolling. On the test piece of 10cm x 10cm from the roll aluminum foil.

Technological process

Plasma cleaning - bias voltage sputtering (Ni Cu alloy) - plated copper or tin plating.

In the field of electronic applications, to add the aluminum conductive and weldability, demand in the appearance of electroplating copper and tin metal, the current many domestic and foreign research mostly use chemical way, prepreg and electroless plating combined and disposal technology is mixed and disorderly. The author through a lot of experiments, the choice of surface plasma cleaning and magnetron sputtering intermediate layer of pre disposal methods and technology of electroplated, on the surface of the aluminum obtained crystalline detailed, bright, good weldability, combined with strong copper, tin. In aluminum foil surface electroplating certain thickness of copper to replace the use of copper foil, widely used in electromagnetic shielding category, printed circuit boards and lithium ion battery fluid, and save a lot of copper; can be singly used for electroplated coatings of tin or copper and tin coating and application in some new electronic category.

Technical introduction

Data

The hard light foil with a thickness of LG3 is used to 0.033mm the high purity aluminum rolling. On the test piece of 10cm x 10cm from the roll aluminum foil.

Technological process

Plasma cleaning - bias voltage sputtering (Ni Cu alloy) - plated copper or tin plating.