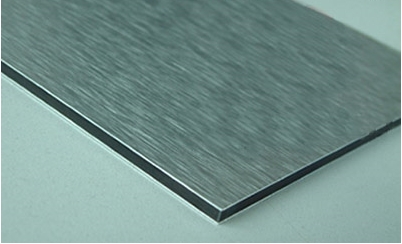

Brush aluminum plastic composite panel

| Total thickness | 3mm; 4mm | |

| Aluminum thickness | 0.21mm, 0.3mm, 0.4mm, 0.5mm | |

| Width |

1220mm,1250mm(standard width) 1000mm,1500mm,1550mm (non standard width) |

|

| Length | up to 6000mm | |

| Dimensional Tolerances | ||

| Thickness | 0.02 mm | |

| Width | -0/+2mm | |

| Length | 1000 - 4000 mm | -0/+4mm |

| Length | 4001 - 6000mm | -0/+6mm |

Characteristics of brush aluminum composite panel

- Excellent fireproof property

- Super peeling strength

- Perfect cold resistance performance

- Excellent surface flatness and smoothness

- Superior weather, corrosion, pollutant resistance

- Even coating, various colors

- Superior impact resistance

- Lightweight and easy to process

- Easy to maintain

Application scope of brush aluminum composite panel

- Gas piping, cables, building materials, etc (this product fills a gap in the domestic construction materials field, with performance indexes superior to panels manufactured overseas)

- Curtain wall decoration for buildings where security is important, such as airports, hospitals and research centers

- Curtain wallboards for outside walls of normal buildings

- Renovations of old buildings and movable houses

- Reformation and decoration for indoor walls, ceilings, bathrooms, kitchens and balconies

- Facades

- Billboards, exhibition desks and notice boards

- Wallboards and ceilings for tunnels

- Materials for industrial application, car and ship bodies

Note:Color Match of the aluminum composite panel

1. For custom color requests, we can deal as following:

A.Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

B.New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days. C.Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

2.For general colors, please refer to our color chart

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective

film when installing to avoid any color difference by vision.