You are here:

>

News

>

Hardware requirements for maintenance of aluminum body

Hardware requirements for maintenance of aluminum body

1. Aluminum body special gas welding machine and shape repair machine

Because of the low melting point of aluminum, the welding requirements of low current, so it is necessary to use special aluminum body gas welding machine.

2. Special aluminum body repair tool, strong rivet gun

Repair of aluminum body most of the use of the repair method, which must have a strong rivet gun. And repair of aluminum body tools must be dedicated, and can not repair steel body tool mix.

3. Explosion-proof dust collection system

In the process of grinding aluminum, will produce a lot of aluminum, aluminum powder not only harmful to the human body, but also flammable and explosive, so it should have a dust collection system in a timely manner to absorb dust

4. Independent maintenance space

Due to the aluminum body repair process requires strict, to ensure the quality of automobile repair and maintenance operation safety, to avoid the aluminum powder on the workshop pollution and explosion, to set up a separate aluminum body repair station.

Maintenance operation of the attention

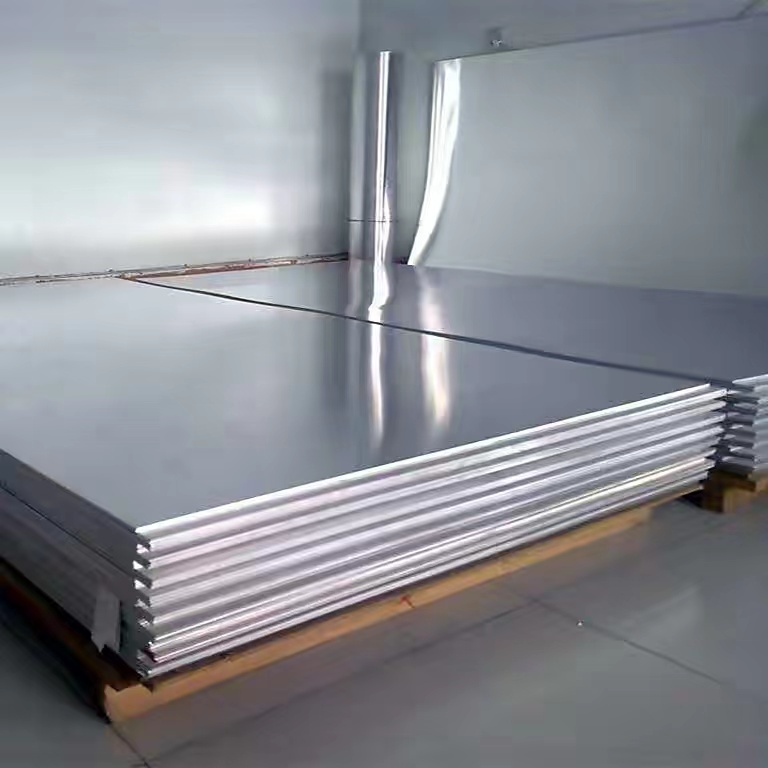

1. Aluminum alloy plate of the local tensile is not good, easy to produce crack.

2. The size of the accuracy is not easy to grasp, it is difficult to control the rebound. In the maintenance of the use of low temperature heat release should be used to release the stress method, so that it will not produce a rebound and other two deformation phenomenon.

3. To carry out the cleaning of the mold, equipment, the environment of dust, air pollution and other aspects to take appropriate measures to ensure the integrity of parts.

Because of the low melting point of aluminum, the welding requirements of low current, so it is necessary to use special aluminum body gas welding machine.

2. Special aluminum body repair tool, strong rivet gun

Repair of aluminum body most of the use of the repair method, which must have a strong rivet gun. And repair of aluminum body tools must be dedicated, and can not repair steel body tool mix.

3. Explosion-proof dust collection system

In the process of grinding aluminum, will produce a lot of aluminum, aluminum powder not only harmful to the human body, but also flammable and explosive, so it should have a dust collection system in a timely manner to absorb dust

4. Independent maintenance space

Due to the aluminum body repair process requires strict, to ensure the quality of automobile repair and maintenance operation safety, to avoid the aluminum powder on the workshop pollution and explosion, to set up a separate aluminum body repair station.

Maintenance operation of the attention

1. Aluminum alloy plate of the local tensile is not good, easy to produce crack.

2. The size of the accuracy is not easy to grasp, it is difficult to control the rebound. In the maintenance of the use of low temperature heat release should be used to release the stress method, so that it will not produce a rebound and other two deformation phenomenon.

3. To carry out the cleaning of the mold, equipment, the environment of dust, air pollution and other aspects to take appropriate measures to ensure the integrity of parts.